Hyfi

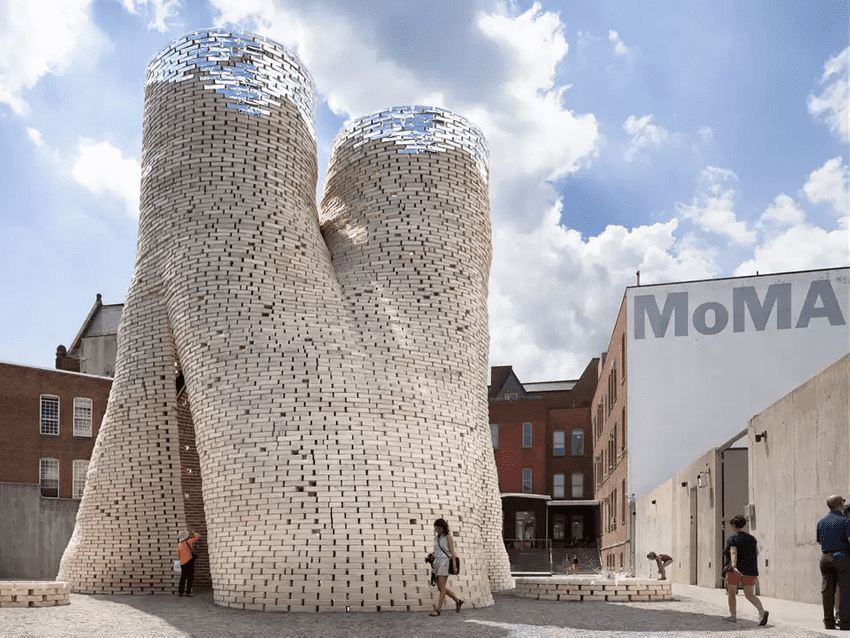

An installation designed using custom Python geometry and optimization algorithms embedded within Autodesk Revit and Dynamo models. The installation was commissioned and built as part of the Young Architects program, which takes place every summer in the courtyard of the MoMA PS1 museum in Queens, New York. The installation consisted of a 30 foot tall structure constructed almost entirely out of compostable bricks made from a combination of repurposed agricultural waste and Mycelium (the root structure of mushrooms).

A material system

The entire structure consisted of over 10,000 of these bricks, which were grown in a facility in upstate New York over the course of 6 weeks. The growing process involved first creating the mixture of agricultural waste and mycelium, and then packing it into molds which were produced by vacuum forming over a base shape.

One issue we came across during design and material testing is that the bricks proved fairly durable as long as the outer layer was preserved. However cutting the bricks in any way would expose the looser insides and significantly reduce their structural capacity.

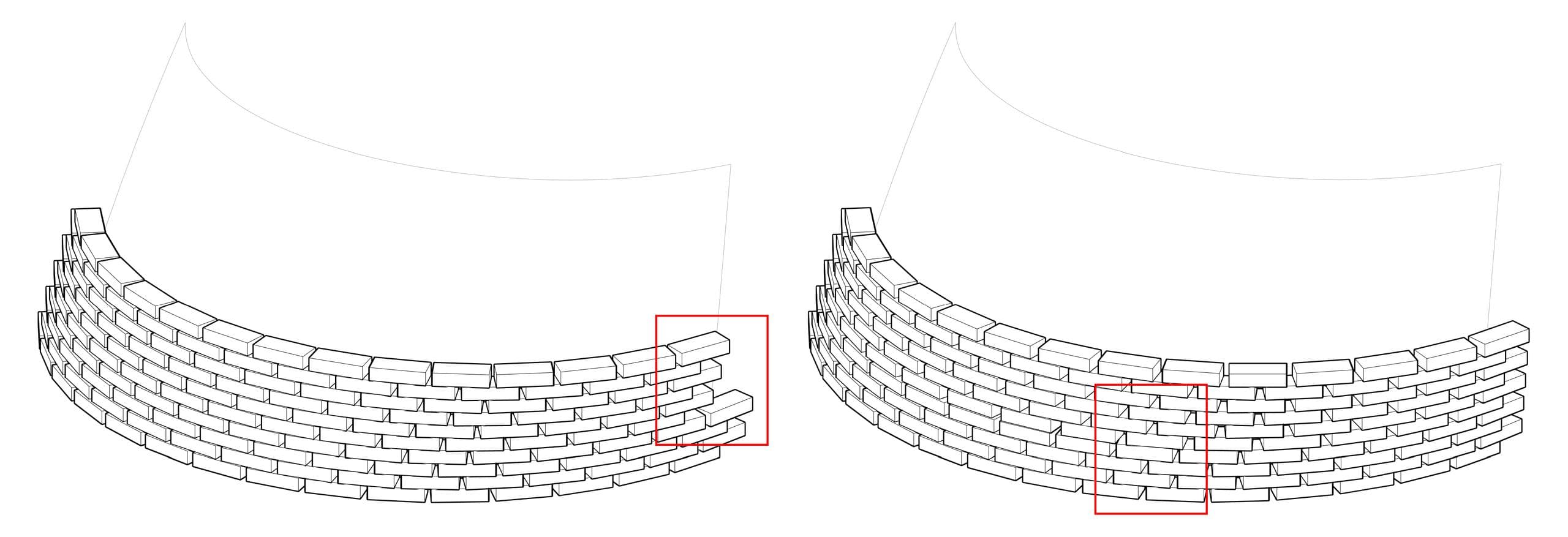

This meant that we would not be able to cut the bricks on site to fill out varying courses, as is typically done in bricklaying for describing complex surfaces. The geometry we were trying to produce, however, was doubly curved - starting out wider at the bottom and narrowing toward the top. This meant that the courses changed length gradually as they went up, which in turn meant that the structure was not possible to construct of only a single brick size while ensuring that gaps were minimized and proper bearing conditions were met.

Initial brick stacking tests, showing issues with description of doubly curved surface: incomplete coursing (left) and improper bearing (right)

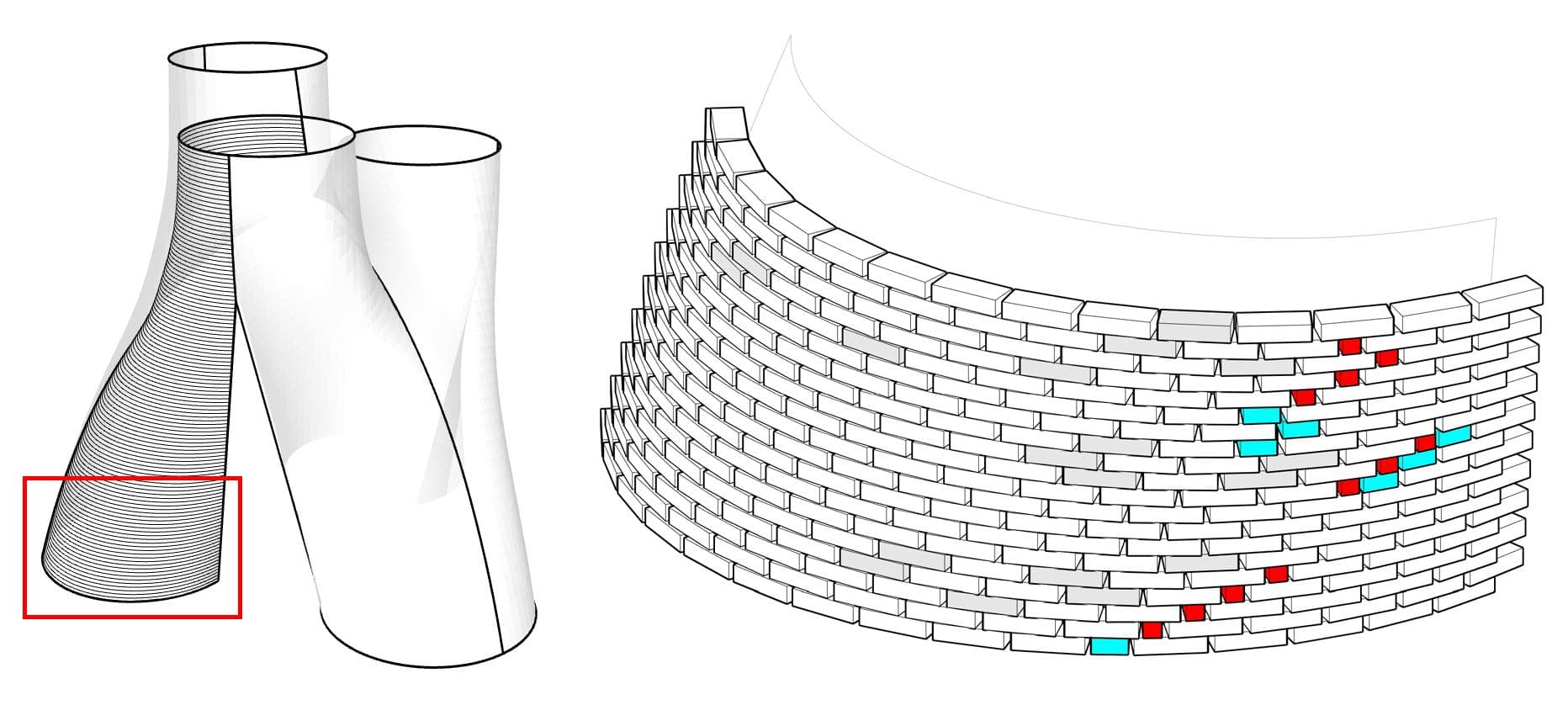

While the growing process allowed virtually any brick shape to be produced (within the constraints of vacuum forming), economies of scale in how the molds were produced and reused during the process meant that only a few variations could feasibly be produced. In the end we settled on only three variations: a full size brick measuring 16" wide, a half-size brick at 8" and a quarter-size brick at 4".

Diagram showing courses cut over the entire structure, and a zoomed-in section showing the three brick sizes being used to describe the surface.

Computing a solution

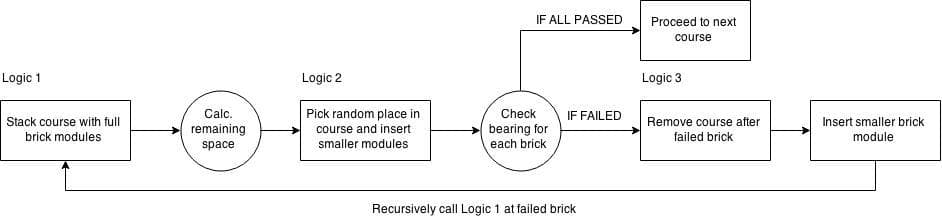

The next challenge was figuring out a way to describe our surface using just those three sizes in a way that ensured that gaps were minimized and proper bearing between courses was maintained. While we tried a variety of top-down approaches, we could not find a single deterministic method which could perfectly solve the problem. Instead, we ended up developing a bottom-up method using concepts of recursion and agent-based systems.

Diagram of agent-based system using recursive logic

In the system, each brick is represented as an agent which is instantiated in the course one after the other. Once an entire course is laid, Each brick agent can check to make sure the course is being filled efficiently and can also check for proper bearing with the course below. If an issue is detected, the problem brick and all the bricks after is deleted, a different module size is put in its place, and the processes is run again.

Once we had this script, we could run it over all the courses cut from the surface to create the entire structure. The file generated by this process was then used to create paper templates of each course, which were then used on site to properly lay out the bricks before setting them.

The computational approach we used to create the brick layout for this project was later published as a paper for the Design Modelling Symposium that was held in Copenhagen in 2015.

Computational Brick Stacking for Constructing Free-Form Structures. Modelling Behaviour, proceedings of the Design Modelling Symposium, Copenhagen. Springer International Publishing. (2015) [pdf]