A320 Bionic Partition

A 3d-printed aircraft component designed for Airbus using custom computational design and optimization software written in Python, Javascript, and D3. The A320 Bionic Partition was a joint research project by Autodesk Research and Airbus investigating applications of Generative Design and Additive Manufacturing for the aerospace industry.

to investigate combined applications of new methods of additive manufacturing being developed at Airbus with new AI-driven design methods we were developing at Autodesk Research. The outcome of the project was a full-scale manufactured prototype of an A320 partition designed through novel computational methods which combine nature-inspired algorithms with genetic optimization techniques to optimize the structure of industrial components.

The component

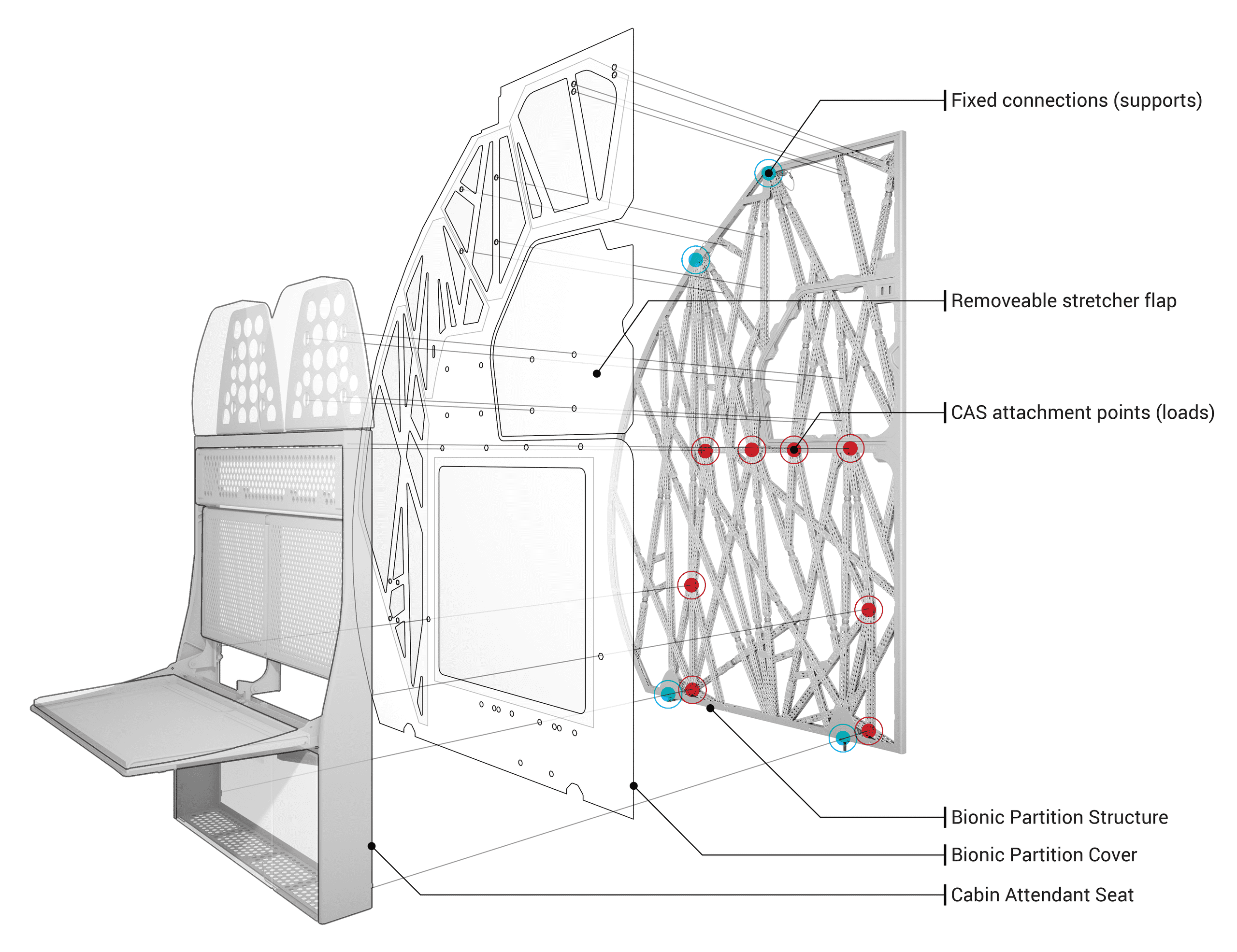

As a test case for the new methods we were developing we chose the A320 interior partition, with the goal of reducing its weight by 50%. The partition is a complex structure due to its need to support a cabin attendant seat and include a removable stretcher flap, both of which impose significant structural demands.

A new approach

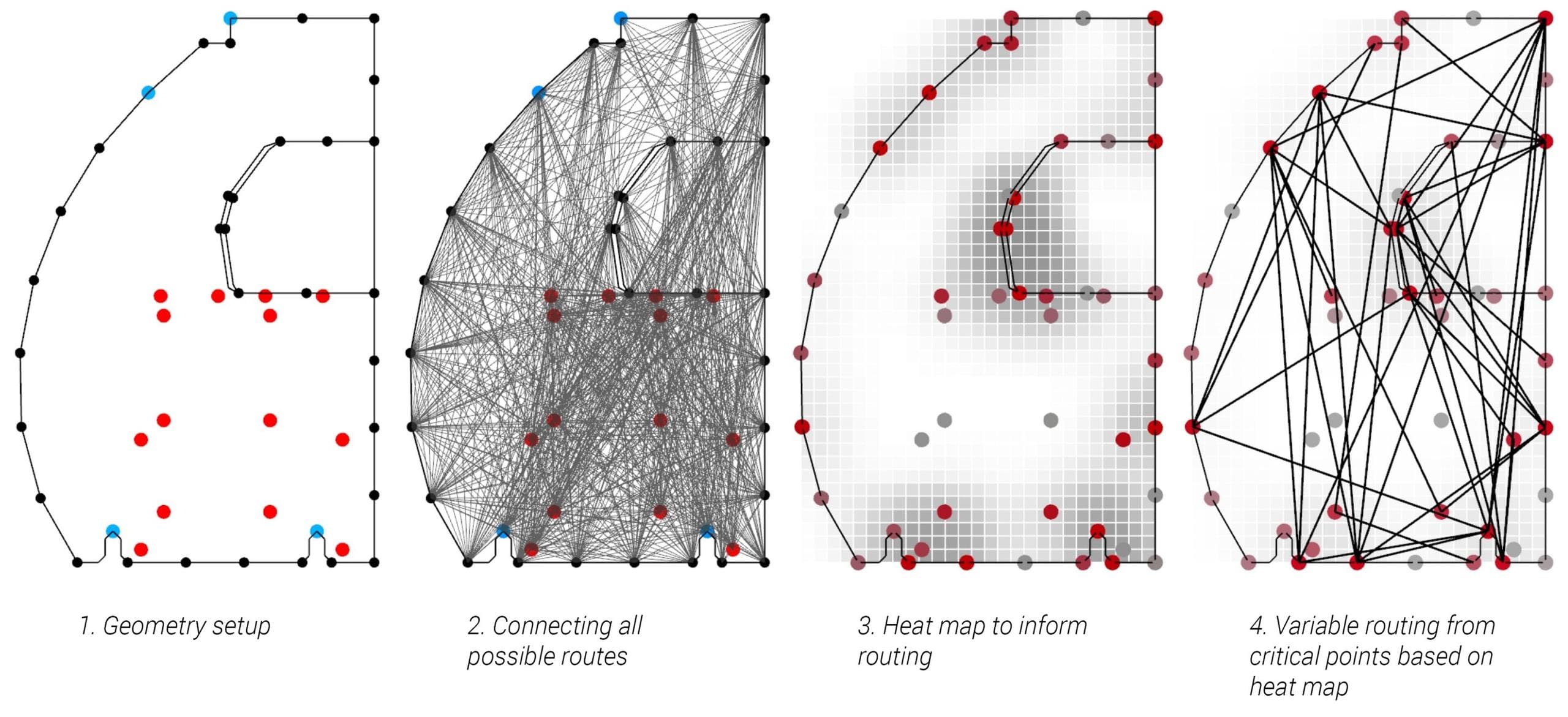

Our approach combines a bottom-up agent-based algorithm inspired by slime mold growth with a top-down genetic algorithm for optimization. The slime mold-inspired algorithm creates a network of connections between key structural points, mimicking the mold's ability to form efficient, resilient paths. This growth process is then optimized using a genetic algorithm, which refines the design by minimizing weight and maximizing structural performance based on engineering requirements, such as stress distribution and displacement limits.

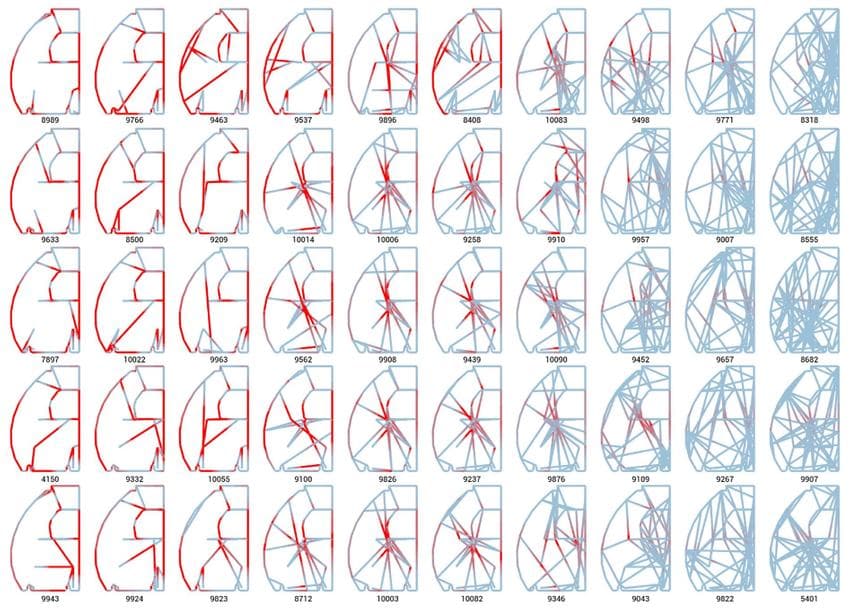

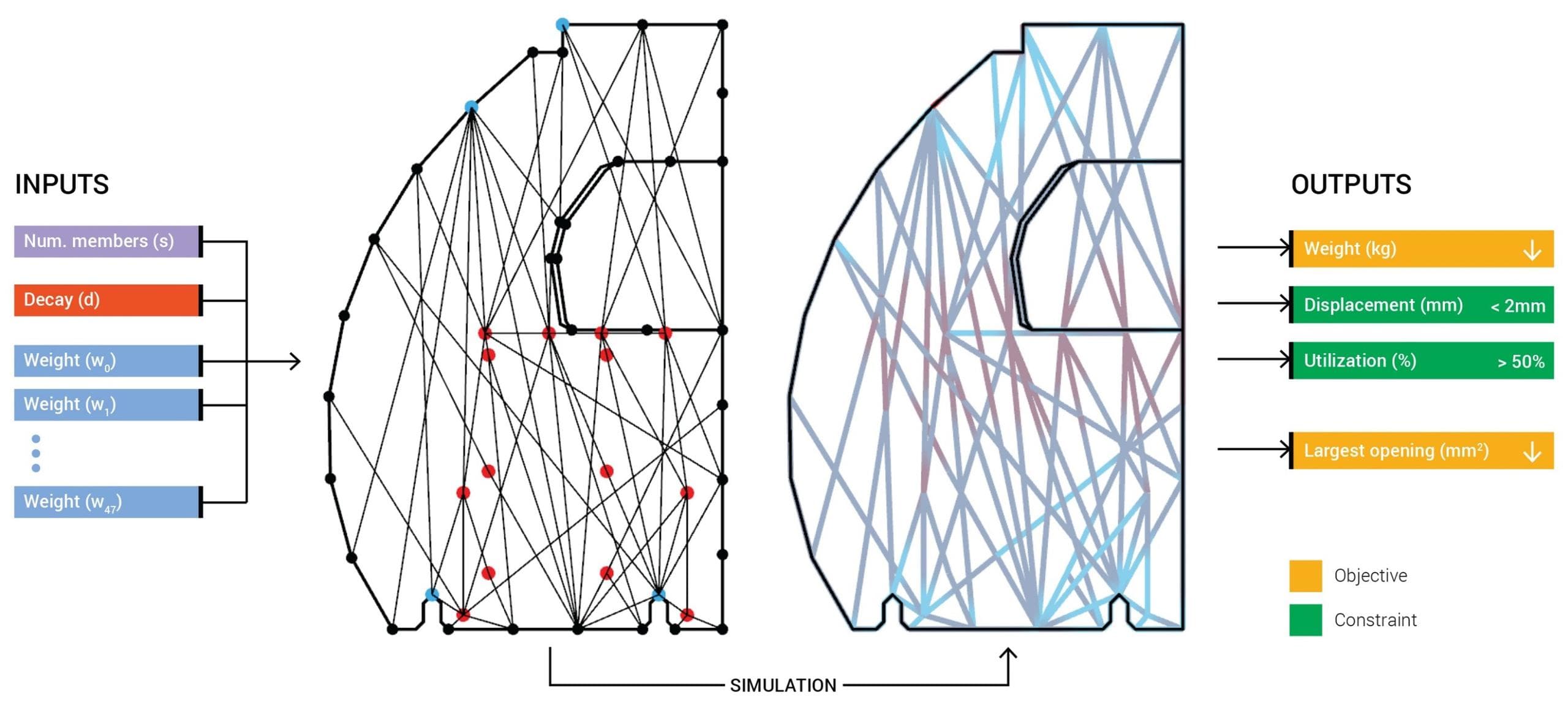

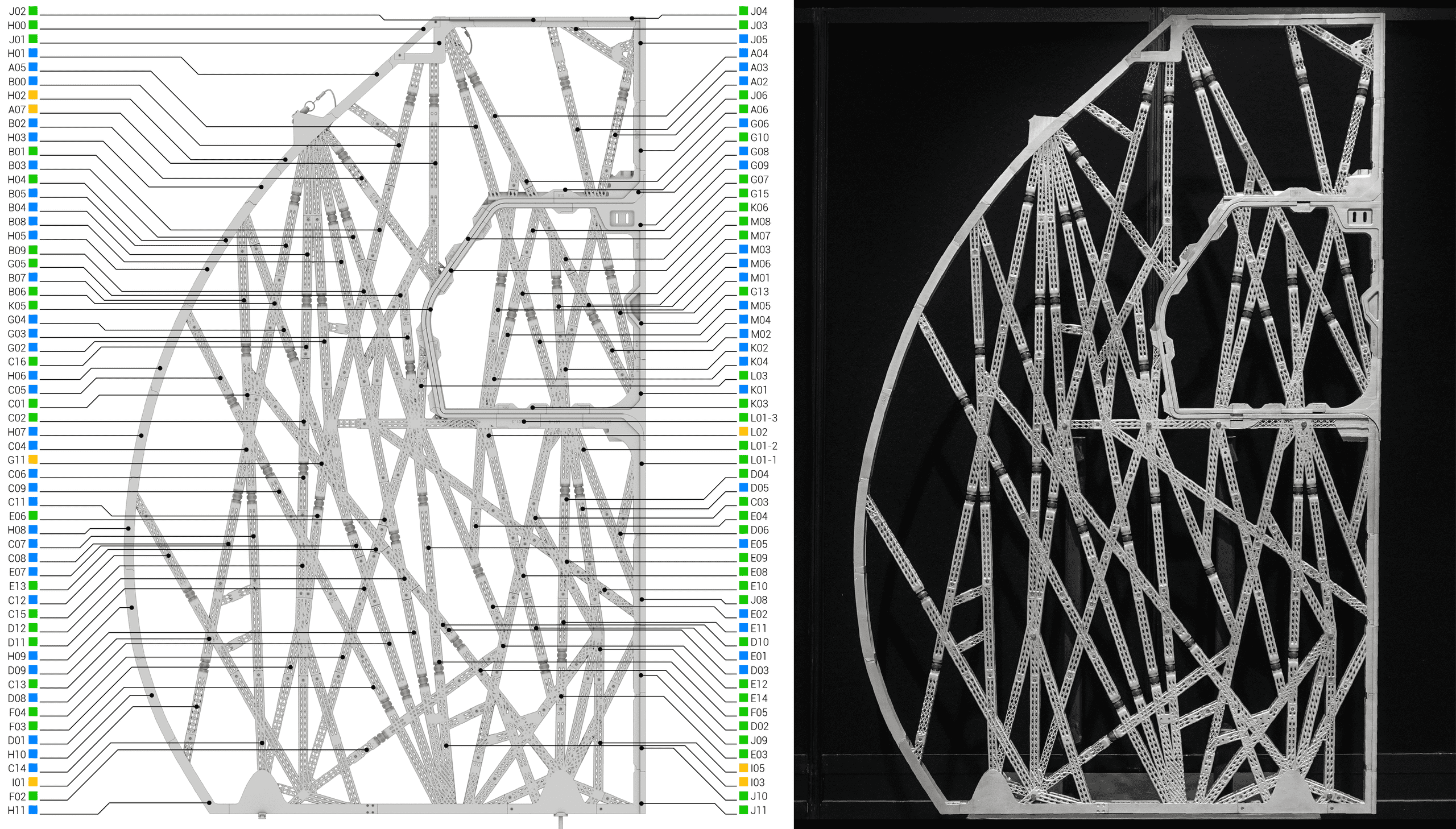

Diagram of generative model based on slime mold which is able to produce a variety of design options driven by a small set of numerical inputs

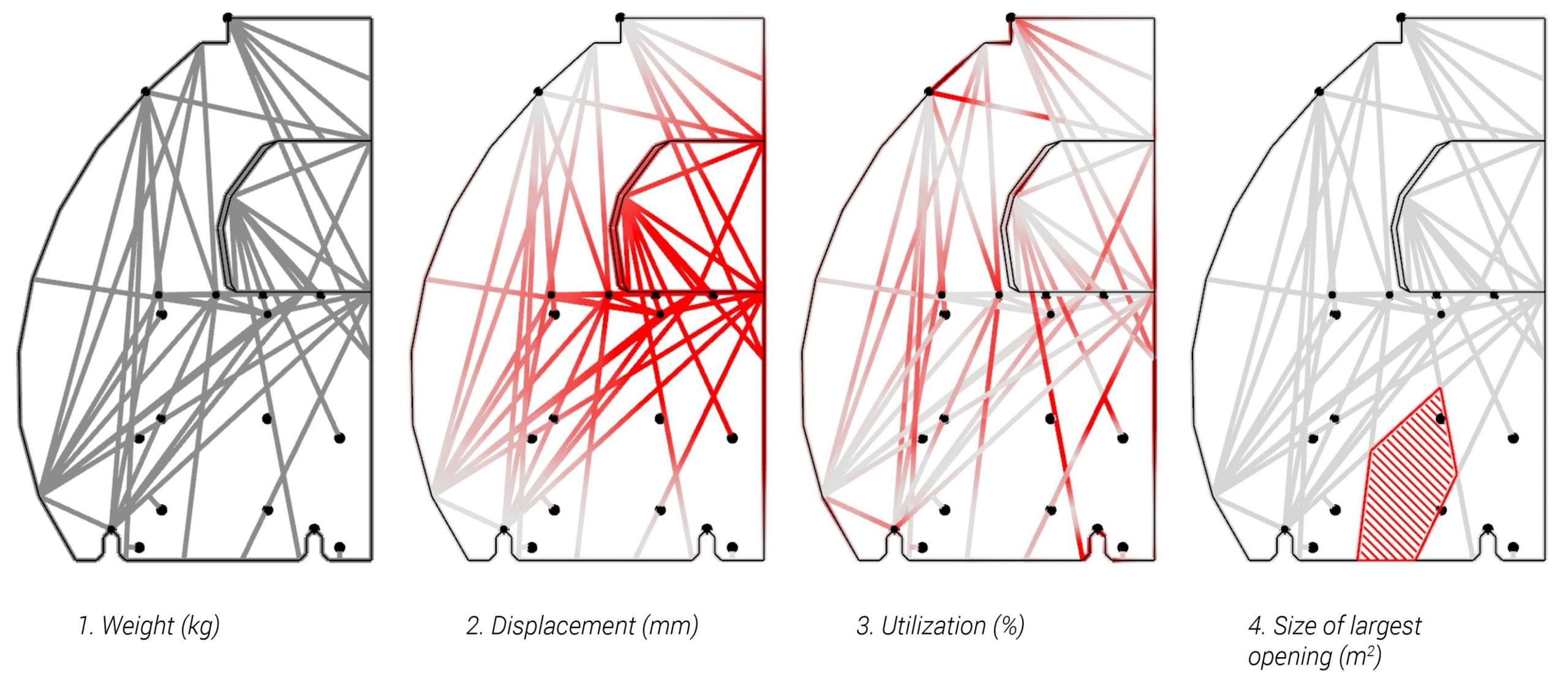

Performance metrics used to evaluate each option produced by the generative model

System diagram showing set of numerical inputs which produce each design option, which are then evaluated through simulation to derive the numerical outputs used to score each option

The system's design process is particularly suited to the capabilities of metal additive manufacturing, which allows for the creation of complex geometries that would be difficult or impossible to produce with traditional methods. By leveraging the formal freedoms offered by 3D printing, we were able to explore a vast design space and produce highly optimized, lightweight structures.

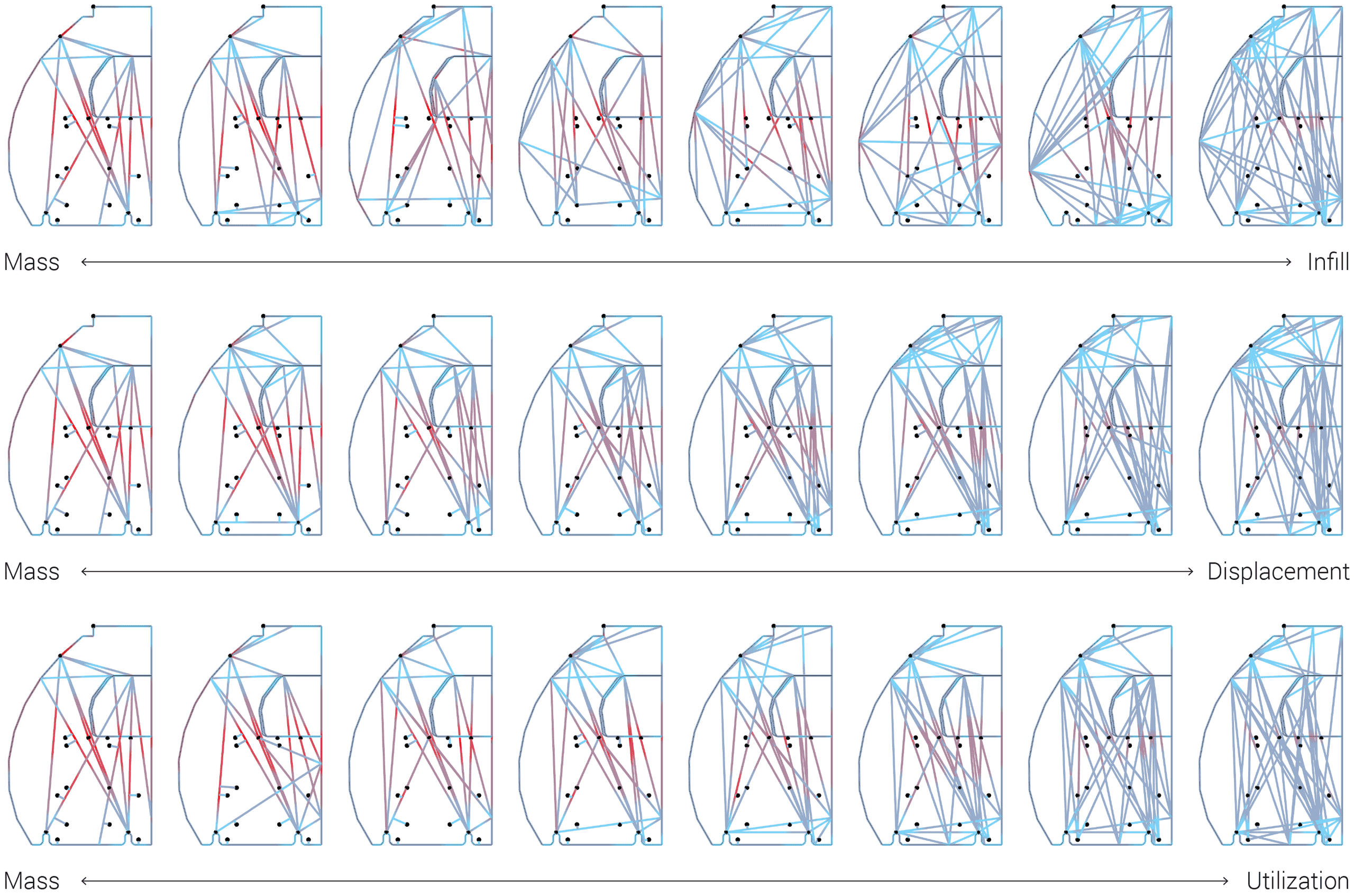

Sample of designs showing trade-offs between sets of two objectives

The optimization process involved using finite element analysis (FEA) to evaluate the structural performance of each design iteration, with objectives to minimize weight and structural weaknesses while avoiding large holes in the partition. The genetic algorithm was able to find a set of "Pareto optimal" designs, balancing the trade-offs between weight reduction and structural integrity.

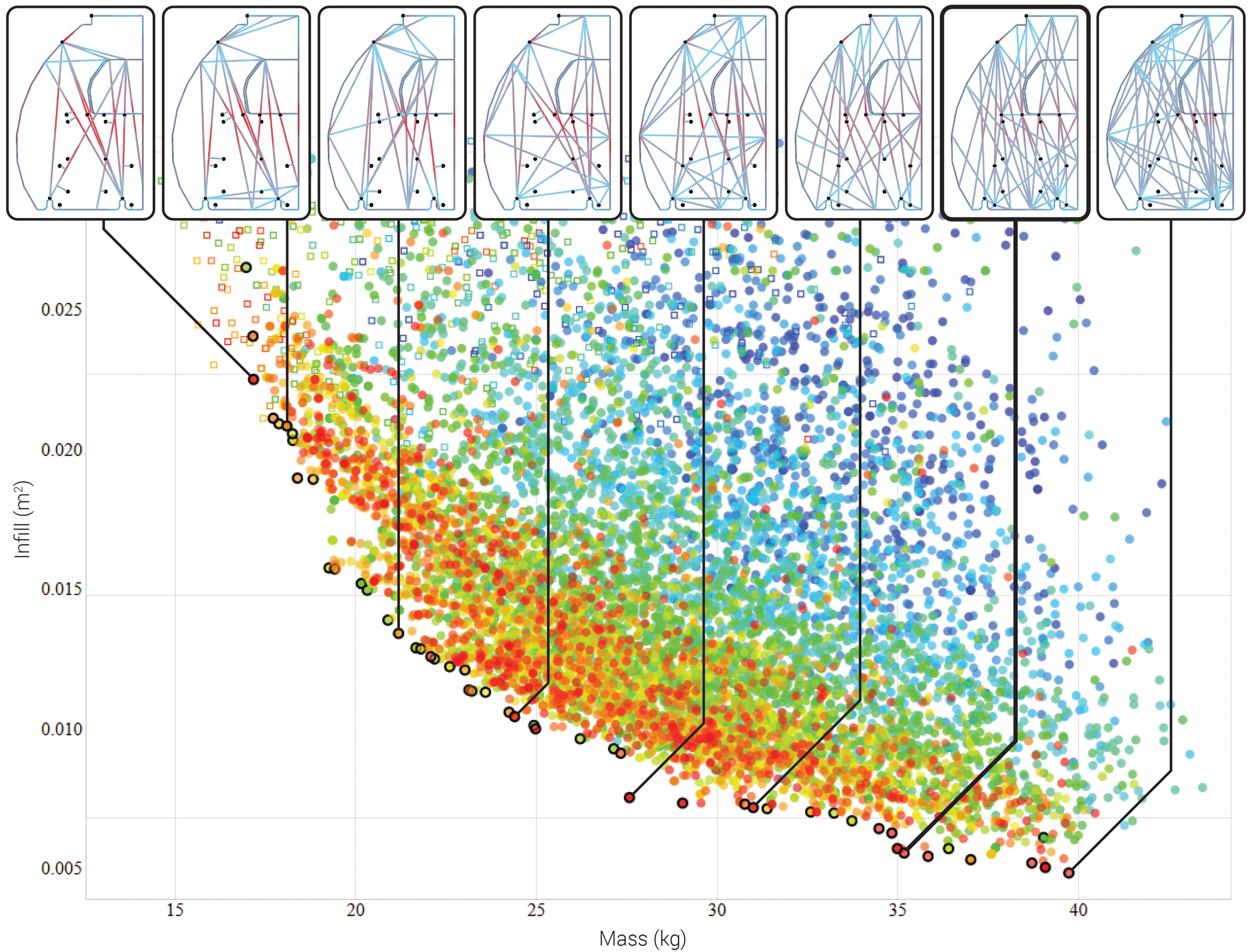

All designs explored during the optimization process plotted according to the two objectives. Color represents the generation in which the design was evaluated, with blue for earlier and red for later designs. Designs with a black outline are part of the Pareto-dominant set of optimal solutions

The final design achieved the target of a 50% weight reduction while maintaining the necessary structural performance. This innovative approach resulted in the largest aircraft component ever produced entirely through metal additive manufacturing. The system exemplifies the potential of combining nature-based algorithms with advanced manufacturing techniques to solve complex design challenges in the aerospace industry and beyond.

Publication

This project was published in the proceedings of the Design Modelling Symposium 2017 Conference in Paris, France.

Nature-based Hybrid Computational Geometry System for Optimizing Component Structure. Humanizing Digital Reality, proceedings of the Design Modelling Symposium, Paris. Springer International Publishing. (2017) [pdf]